Butterfly Valve & TOV

In 1951 Keystone Valves launched a new valve concept - the rubber seated butterfly valve. Since then, through constant innovation and customer feedback, Emerson offers trims and sizes of butterfly valves to suit most applications having to do with isolation and control of liquids, gases or slurries. By both mechanical and polymer engineering Keystone butterfly valves have a strong focus on providing valves that offer long life through high cycle capabilities. Benchmarking ensures Keystone remains a leader in this critical area against other makers of butterfly valves for the process sectors.

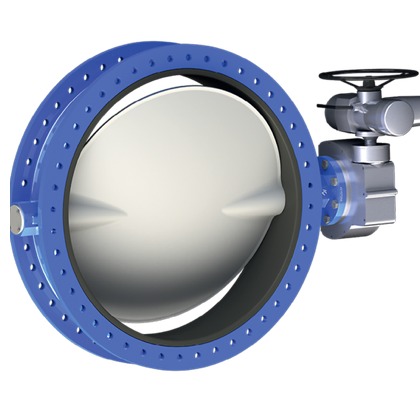

The RMI Dubex double flanged triple eccentric resilient seated butterfly valve provides adjustable torque seating and non rubbing seal to seat contact, which sets it apart from conventional double flange single or double eccentric position seated butterfly valves. While the valve functions as a device for the isolation and control of water pipelines in diameters from 150 – 3000mm, the design also allows for reliable rubber lining of exposed metallic components making the valve suited for saline water cooling applications in power stations.

The Sapag range provides Process and Water customers with innovative designs capable of high pressures and high velocities as standard. A comprehensive range of materials makes the product suitable for water treatment, desalination and chemical facilities.

Vanessa was the first company in the world to introduce a Triple Offset Valve (TOV) with true zero leakage* performance creating a new industry category using a technology not previously available with other standard quarter turn valves.

Our triple offset design completely eliminates any rubbing action of the sealing elements during the 90 degrees of rotation, positioning Vanessa as the ultimate process valve. Based on these new and revolutionary concepts, we have achieved worldwide success across the Oil & Gas, Process and Power industries.